Solutions

RIFAST Equipment

Offline Process Solutions

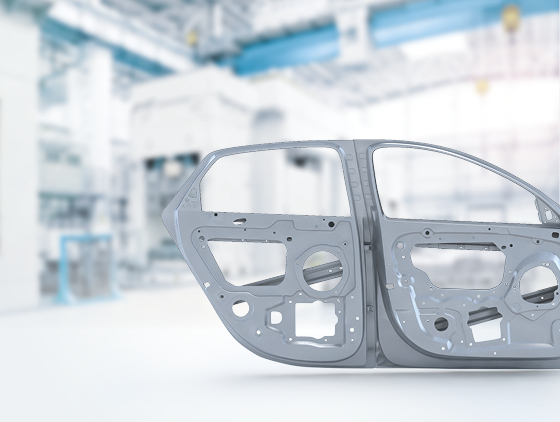

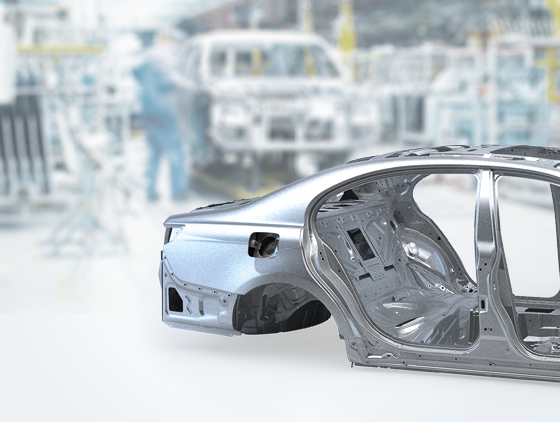

Complex Installations Outside a Stamping Press

C-frame equipment supports offline or robotic cell installation of fasteners. Offline C-Frames can be configured to install multiple different fasteners with simple change-over between fastener installations. The C-frames are designed to support or install a specific fastener design, but the C-frame feeding unit can support multiple C-frames installing the same fastener. Offline (C-Frame) operations may be necessary because a stamping has 3 (or more) different fasteners in it, or because the location of the installed fastener is not possible in a stamping press due to size or location.

RIFAST Equipment

Offline process solutions

Complex Installations Outside a Stamping Press

C-frame

Pneumo-Hydraulic

The robust and very flexible c-frame platform with up to 320 kN installation force by 5 - 8 seconds cycle time. With and without safety functions.

RIFAST C-Frames are characterized through high standardization and modular design. This allows the customer to select the right C-Frame for the respective application. Whether it’s a full-automatic C-Frame for body frame construction in a robot cell, as a semi-automatic workstation, or as a flexible manual workstation. The RIFAST C-Frame product program always offers the right solution for your application.

High standardization economic pricing, shorter lead times, long product lifetime thanks to robust and proven components

C-frame electric

Servo drive

The robust and very fast c-frame platform with up to 150 kN installation force by 3 - 8 seconds cycle time. With and without integrated safety system.

Thanks to the standard and modular design there is a suitable C-Frame available for every application. Whether it’s a full-automatic C-Frame for body frame construction in a robot cell, as a semi-automatic workstation, or as a flexible manual workstation. The new RIFAST CSE product program always offers the right solution. The servo direct drives are available with up to 150 kN installation force capabilities and for the manual workstation we offer at 150 kN variation available with integrated safety system. Through remote diagnostic routers we can quickly diagnose the equipment remotely and consult on trouble shooting solutions.

The RIFAST C-frame with servo direct drive advantage

CZM/CZB

C-frame feeding unit

The robust and reliable c-frame feeding system platform for all RIFAST bolt and nut functional elements. Up to 20 strokes/min with 4 lanes.

The compact RIFAST C-frame feeding unit is optimized for the use of RIFAST functional elements to guarantee a high availability and less maintenance. The big bunker system enables the customer to produce for several hours independently. By the use of reproducible machined vibratory bowls it is possible to supply cost-effective up to 4 C-frames with only one feeding unit.

The RIFAST C-frame feeding unit advantage