RIFAST Engineering

Engineering Expertise

A Full Service Provider

As a system supplier we provide a very comprehensive offer of engineering services. Our philosophy is to design first class functional elements based on validated and proven engineering standards that are specific to RIFAST and that perfectly fit to our processing equipment. We thus ensure uncompromising robustness in the technical performance and in the same time we generate scale effects that make mass production much more stable and cost efficient while ensuring top quality.

However, we know how important it is to be able to provide custom solutions to the customers‘ demands. Our engineering standards make specific designs possible while ensuring the same level of performance. Our engineering services include fasteners‘ design, specific recommendations for the best clinching interface on the metal part and a comprehensive functional validation. Upon demand we can perform specific testing and qualification in your specific application.

RIFAST Engineering

Core Capabilities

Design, Simulation, Testing

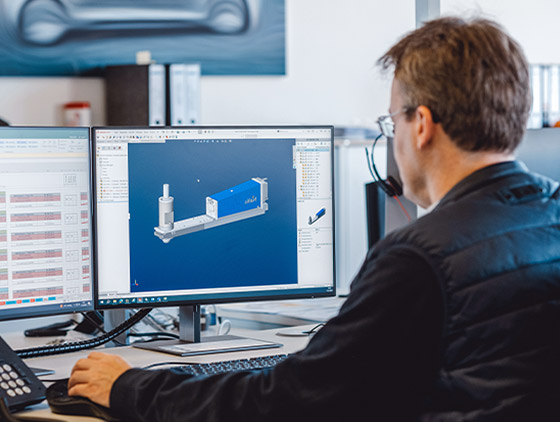

Design

Our engineering standards meet your specific demands

At RIFAST we design standard product platforms that we fully validate before market launch. By doing so, we make sure that our products will work in the defined range of applications and that we provide verified answers to our customer demands. Our references are always the major automotive car makers standards and specifications.

In case an existing product is not suitable, we design specific products based on our proven engineering standards, ensuring the same level of performance.

Testing

A large range of testing facilities

In our application labs, we are able to test all standard specifications for clinching fasteners. We make sure that our products will fulfill the specifications in every specific customer‘s application . Our facilities include following test equipment:

• Installation equipment for RIFAST elements

• Push-out test of the RIFAST joint

• Torque test of the RIFAST joint

• Watertightness test of the RIFAST joint

• Photo documentation of the RIFAST joint

On special demand we can support our customers regarding

• Cross cut of the RIFAST joint

• Assembly test of the RIFAST joint

• Pull-through test of the RIFAST joint

• Bending test of the RIFAST joint

• Prototype assembly with RIFAST elements by our prototype partners

Beyond these specific mechanical joining tests, our parent company RIBE can provide support regarding fasteners validation, including:

• Corrosion testing

• Friction testing

• Clamping force evaluation

• Metallography, hardness

• Hardness measurement

• Dynamic tests

Simulation

Product and process simulations as design supports

Especially when designing innovative products and processes it is critical to validate manufacturability and functional performance at early project phases. We are using simulation softwares to evaluate both before starting our prototype phases.

This pre evaluation is followed by a design validation phase based on machined or cold formed prototypes and then a process validation phase. This standard development steps are the pre-requisite to any product platform’s market launch.