Advantages without pre-punch operation

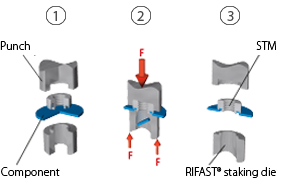

Installation process STM

______________________________________

1) Positioning

2) Punching & Installation

3) Final condition

RIFAST® Self Piercing Process

With the RIFAST® punching process our self piercing nut (STM) is installed into an unperforated sheet metal in one stroke where it punches the hole required for the fastening and the sheet metal material flows to the undercut areas of the punch edge. This creates a fastened joint that provides superior resistance to push-out and torsional forces.

- Self Piercing Nuts: M5 to M10

- For sheet metal thicknesses of 0.6 to 2.0 mm

- Superior resistance against push-out and torsional forces

- Lowest possible component distortion in installation area

- Very high positioning accuracy

- Water-tight joint

- Highest cost-effectiveness thanks to reduction of tool stations