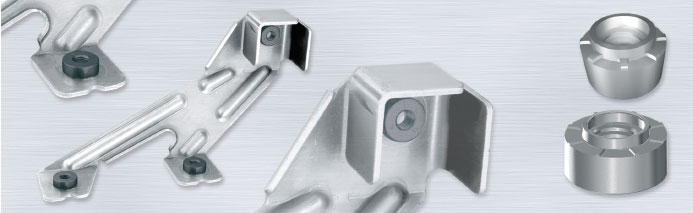

Solutions

for special

requirements

for special

requirements

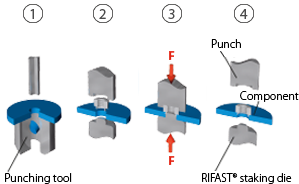

Installation process DBM/LBM

______________________________________

1) Pre-punch operation

2) Positioning

3) Installation

4) Final condition

RIFAST® Riveting

RIFAST® riveting uses the lightweight nut (LBM) and the thick sheet metal nut (DBM) for pre-punched components. The component itself is only exposed to minor stresses because the pilot of the nut is expanded in the punched hole.

- Lightweight nuts M5 to M8

- Sheet metal thicknesses 1.0 mm to 4.0 mm

- Flat, non-distorted component surface after riveting

- Specially developed for lightweight applications

- Considerable weight savings (LBM is ~ 70% lighter than our STM product line)

- Better access due to more compact construction

- Cost reduction through Lightweighting

- Thick Sheet Metal Nuts: M5 to M12

- Sheet metal thicknesses > 2.0 mm

- Flat, non-distorted component surface after riveting

- Can also be used for component materials with low forming capacity

- Superior resistance against push-out and torsional forces

- Water-tight joint